How is Color Reproduced?

Throughout history, reproducing the colors we see in nature has taken many forms. The media and methods used to reproduce color include paintings, printing presses, color file, color monitors, color printers, etc. There are only two basic was, however, of reproducing color – additive and subtractive.

Additive Color System (RGB)

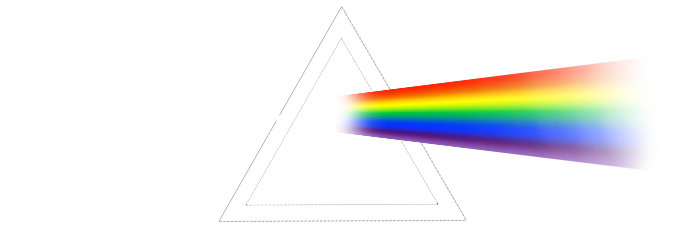

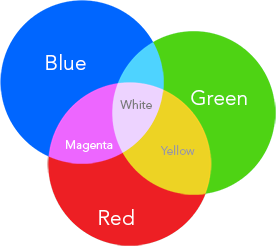

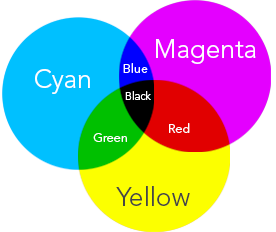

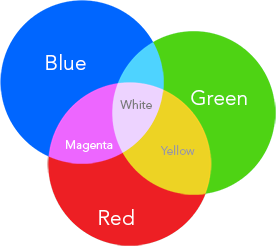

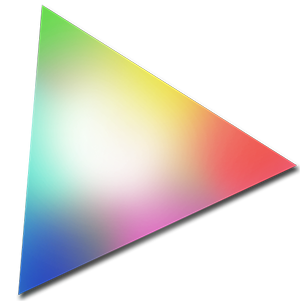

The additive color system involves light light emitted directly from a source, before it is reflected by an object. Light of a specific color, or wavelength (for example, a theatrical spotlight), can be produced by directing white light through a special filter that allows the desired wavelength to pass blocks others. The additive reproduction process mixes various amounts of red, green and blue light to produce other colors. Combining one of the additive primary colors with another produces the additive secondary colors cyan, magenta, and yellow.

To illustrate this, imagine three spotlights, one red, one green and one blue focused from the back of an ice arena on skates in an ice show. Where the blue and green spotlights overlap, the color cyan is produced; where the blue and red spotlights overlap, the color magenta is produced; where the red and green spotlights overlap the color yellow is produced. When added together, red, green and blue lights produce what we perceive as white light.

Television screens and computer monitors are examples of systems that use additive color. A mosaic of thousands of red, green and blue phosphor dots make up the images on video monitors. The phosphor dots emit light when activated electronically. It is the combination of different intensities of red, green and blue light that produces all the colors on a video monitor. Because the dots are so small and close together, we do not see them individually, but see the colors formed by the mixture of light. Colors often vary from one monitor to another. This is not now information to anyone who has visited an electronics store with various brands of televisions on display. Also, colors on monitors change over time. Currently, there are no colors standards for the phosphors used in manufacturing monitors for the graphics arts industry.

To summarize: Additive color involves the use of colored lights. It starts with darkness and mixes red, green and blue light together to produce other colors. When combined in equal amounts, the additive primary colors produce the appearance of white.

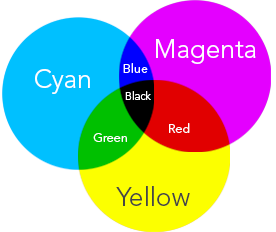

Subtractive Color (CMYK)

The Subtractive color system involves colorants and reflected light. Subtractive color starts with an object (often a substrate such as paper of canvas) that reflects light and uses colorants (such as pigments or dyes) to subtract portions of the white light illuminating an object to produce other colors. If an object reflects all the white light back to the viewer, it appears white. If an object absorbs (subtracts) all the light illuminating it, no light is reflected back to the viewer and it appears black. It is the subtractive process that allows everyday objects around us to show color. Remember the example of the red apple? The apple really has not color. It has no light energy of its own. Colorants in the apple’s skin absorb the green and blue wavelengths of white light and reflect the red wavelengths back to the viewer, which evokes the sensation of red.

The Limitations of Color Reproduction

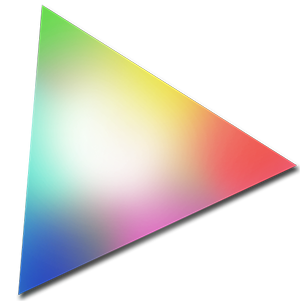

The colors we see in nature represent an extremely wide range of colors. When it comes to reproducing color, however, we run into limitations. No color reproduction system (color film, color monitors, printing presses, etc.) can reproduce the entire range of colors we see in nature.

Color Gamuts

Color gamut is another term for “range of colors.” Each color reproduction system has its own color gamut. For example, the gamut of colors that can be reproduced on photographic film is greater than the gamut of colors that can be produced with process color inks on paper using the offset printing process. Computer screens display more and different colors than can be produced on color film or most color printing devices.

How many colors are there?

If you are a human eye - billions

If you are a computer screen - 16 million

If you are a photographic film - 10 to 15 thousand If you are a printing press - 5 to 6 thousand

Additive Color vs. Subtractive Color

Video monitors use the additive color system. Offset printing uses the subtractive color system. Computer screens display a larger gamut of colors than can be produced on press and by most color printing devices. This is important to know when using the computer as a design tool. The color you see on your computer monitor is probably not what you will get when the job is printed.

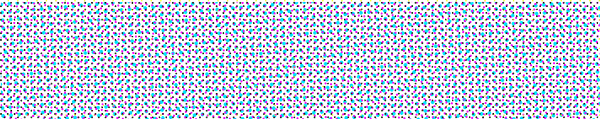

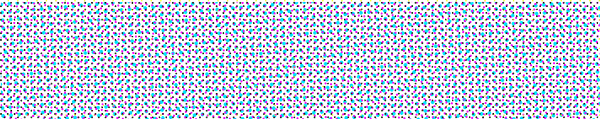

The limitations of the offset printing (subtractive) process are due in part to the image screening process and in part to the type of paper used to print the image. The screening process converts an original continuous-tone image, such as a color photograph, into a pattern of small dots for each process color so the image can be printed with a pigment (wax, toner, ink) or dye on paper. A continuous-tone image shows

a continuous density range between lighter and darker areas. An ink-printable image (screened image) is made up of small dots which creates the illusion of lighter and darker tones. A screened image can be produced using a fixed grid pattern of different-sized dots, or by varying the number of randomly placed, same-sized dots or a combination of the two.

Screening Process & Tone Compression

In offset printing, to be ink-printable, a continuous-tone image such as a photograph is converted into small dots of varying sizes using a camera and a halftone screen or, more commonly, a digital scanner. The original color image is separated into four separate halftone images – one for each of the three process colors and one for black. Historically, reproduction of continuous-tone images has relied on halftone screening methods that produced dots of different sizes in a fixed grid pattern. To be reproducible on press, each area of the original image is converted to a certain dot size to give the same visual appearance as the original image. When printed, areas with larger dots appear darker than areas with smaller dots. The size of each halftone dot is measured in terms of dot area percentage, from 1% to 100%.. In a conventional halftone image, the dot size changes proportionately to the tonal value of the original image.

The coarseness of the grid, or screen ruling, determines the distance form the center of one dot to another. Newer digital screening methods produce very small, similar-sized dots randomly placed, not on a fixed grid. In these screened images, the number of small dots in a given area changes proportionately to the tonal value of the original image. Regardless of the screening method, a continuous-tone image must be converted into small dots to be reproducible on press.

The goal of four-color process printing is to create the illusion of continuous-tone color. Reproducing good tone is considered the first and foremost objective in achieving good color reproduction. The primary factor that limits color reproduction with subtractive color systems is tone compression.